Bar txiav → txias dabtsi yog khoov → sib koom → vuam → thawj calibration → kho cua sov → theem nrab calibration (pov thawj) → tshuaj xyuas. Vuam thiab kev kho cua sov yog cov txheej txheem tseem ceeb hauv kev tsim cov mining round txuas steel saw, uas cuam tshuam ncaj qha rau cov khoom zoo. Kev tshawb fawb vuam tsis tuaj yeem txhim kho cov txiaj ntsig thiab txo cov nqi tsim khoom; Cov txheej txheem kho cua sov tsim nyog tuaj yeem muab kev ua si tag nrho rau cov khoom siv thiab txhim kho cov khoom zoo.

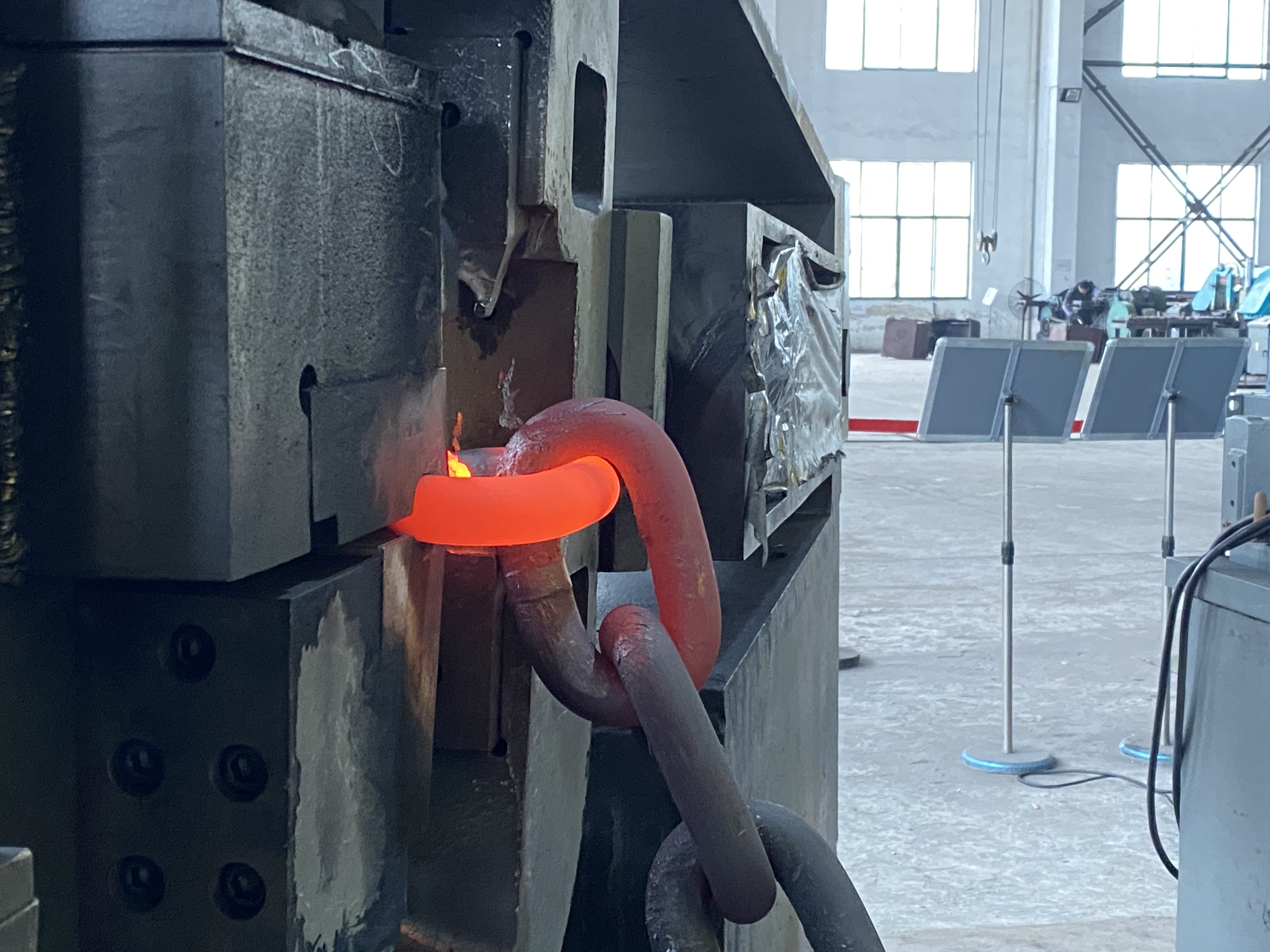

Txhawm rau kom ntseeg tau qhov zoo ntawm kev sib txuas ntawm cov mining round txuas steel saw, phau ntawv arc vuam thiab tiv thaiv pob tw vuam tau raug tshem tawm. Flash taub qab vuam yog dav siv vim nws qib siab ntawm automation, kev siv zog tsawg, khoom ruaj khov thiab lwm yam zoo.

Tam sim no, qhov nruab nrab zaus induction cua sov tsis tu ncua quenching thiab tempering txoj kev yog feem ntau siv nyob rau hauv kev kho cua sov ntawm mining round txuas steel saw. Lub ntsiab ntawm nruab nrab zaus induction cua sov yog tias cov qauv molecular ntawm ib yam khoom yog nplawm hauv electromagnetic teb, thiab cov molecule tau txais lub zog thiab sib tsoo los ua kom sov. Thaum qhov nruab nrab zaus induction cua sov kho yog ua, lub inductor txuas nrog nruab nrab zaus hloov tam sim no ntawm qee zaus, thiab lub workpiece txav ntawm ib qho kev sib tw ceev hauv lub sensor, kom lub induction tam sim no nrog tib zaus thiab kev coj rov qab yuav raug tsim nyob rau hauv lub workpiece, uas yuav hloov lub zog hluav taws xob mus rau hauv lub zog hluav taws xob, thiab lub sijhawm ua haujlwm yuav tsum tau ua kom sov.

Qhov nruab nrab zaus induction cua sov muaj qhov zoo ntawm cov cua kub ceev, tsawg oxidation, zoo quenching qauv thiab austenite grain loj tom qab quenching, uas txhim kho lub zog thiab toughness ntawm cov saw txuas. Nyob rau tib lub sijhawm, nws kuj muaj qhov zoo ntawm kev huv, kev hloov kho yooj yim thiab kev ua haujlwm siab ntau lawm. Nyob rau hauv lub tempering theem, lub siab tempering nyob rau hauv lub saw link vuam cheeb tsam yuav tshem tawm cov quenching nyob rau hauv kev nyuaj siab nyob rau hauv ib tug luv luv lub sij hawm, uas muaj ib tug tseem ceeb heev cuam tshuam rau kev txhim kho cov yas thiab toughness ntawm cov saw txuas vuam cheeb tsam thiab ncua kev pib thiab kev loj hlob ntawm cov kab nrib pleb. Lub tempering kub nyob rau sab saum toj ntawm lub xub pwg yog qis dua, thiab hardness yog siab dua tom qab tempering, uas yog conducive rau hnav ntawm cov saw txuas nyob rau hauv tus txheej txheem ntawm kev ua hauj lwm thiab tiv thaiv lub pob khawm ntawm cov saw txuas thiab sprocket meshing.

Post lub sij hawm: May-10-2021