I. Qhov tseem ceeb ntawm kev xaiv cov chains thiab shackles

Nyob rau hauv cov cement factories, thoob elevator yog qhov tseem ceeb rau kev thauj cov khoom hnyav, abrasive tej khoom xws li clinker, limestone, thiab cement vertically.Round txuas chains thiab shacklesdais tseem ceeb mechanical kev nyuaj siab, ua rau lawv tsim thiab ntau lawm zoo tswj qhov tseem ceeb rau kev ua hauj lwm zoo. Nov yog vim li cas xaiv cov khoom tsim nyog tseem ceeb thiab yuav ua li cas SCIC hais qhov no:

1. Load-Bearing Peev Xwm:Chains thiab shacklesyuav tsum tiv taus siab tensile loads thiab shocks los ntawm tas mus li thoob txav. Cov khoom siv tsis zoo yuav ua rau tsis ua haujlwm tam sim ntawd, ua rau lub sijhawm poob qis, muaj kev nyab xeeb kev nyab xeeb, thiab kev kho nqi kim. SCIC txoj kev ua raws li DIN cov qauv ua kom ntseeg tau tias peb cov khoom ua tau raws li qhov yuav tsum tau muaj lub zog, xws li lub zog tawg ntawm 280-300 N / mm².

2. Hnav Resistance: Lub abrasive yam ntawm cov ntaub ntawv cement ua rau kom hnav ntawm lub elevator Cheebtsam. Case-hardened chains (txog 800 HV) thiab shackles (txog 600 HV) muab qhov chaw ruaj khov los tiv thaiv kev puas tsuaj, thaum tuav cov tub ntxhais tawv tawv kom tsis txhob tawg. SCIC cov txheej txheem carburizing meej ua tiav qhov thov 10% carburizing thickness thiab 5-6% zoo hardness qhov tob, kom ntseeg tau tias kev ua haujlwm ntev.

3. Kev Ua Raws Cai: Ua raws li DIN 764, DIN 766, DIN 745, thiab DIN 5699 lav tiaschains thiab shacklesua tau raws li cov qauv kev lag luam rau qhov ntev, cov khoom siv, thiab kev ntseeg tau. SCIC cov kws tshaj lij hauv kev ua kom tau raws li cov qauv no ua kom muaj txiaj ntsig zoo raws li cov ntawv thov hnyav.

4. Kev Tswjhwm Zoo: SCIC kev tswj xyuas kom zoo - los ntawm kev xaiv cov khoom siv mus rau qhov kev tshuaj ntsuam zaum kawg - txo qhov tsis xws luag thiab ua kom qhov tseeb qhov tseeb, hardness, thiab lub zog. Qhov kev muaj peev xwm no txo qis qhov ua tsis tau raws li qhov hnyav ntawm cov cement factories.

Xaiv txoj caichains thiab shacklesNws yog ib qho tseem ceeb rau kev ua haujlwm thiab kev nyab xeeb ntawm koj lub thoob of elevator. Ntawm SCIC, peb cov khoom tsim thiab tsim kom tau raws li cov qauv nruj DIN, kom ntseeg tau tias lawv tuaj yeem tiv taus cov khoom hnyav thiab cov khoom siv abrasive uas muaj nyob rau hauv cov cement factories. Nrog rau peb cov kev tswj xyuas kom zoo, koj tuaj yeem ntseeg tau tias peb cov chains thiab shackles yuav muab kev txhim khu kev qha, txo qhov kev pheej hmoo ntawm kev poob qis thiab cov nqi kho.

II. Sib npaug Hardness thiab lub zog thaum tsim khoom

Ua tiav cov neeg siv khoom tshwj xeeb saum npoo tawv (800 HV rau cov saw, 600 HV rau shackles), carburizing thickness (10% ntawm txoj kab uas hla), qhov tob tob (550 HV ntawm 5-6% ntawm txoj kab uas hla), thiab tawg quab yuam (280-300 N / mm²) yuav tsum tau ua tib zoo sib npaug ntawm hardness thiab lub zog. Nov yog li cas SCIC ua tiav qhov no los ntawm kev xaiv cov khoom siv, kev kho cua sov, thiab carburizing:

Cov txheej txheem tsim khoom tseem ceeb

1. Kev xaiv cov khoom siv:High-carbon lossis alloy steels raug xaiv rau lawv lub peev xwm los teb rau carburizing thiab quenching, muab ob qho tib si saum npoo hardness thiab core toughness.

2. Carburizing:Carburizing diffuses cov pa roj carbon monoxide rau hauv cov hlau kom ua kom tawv tawv. Rau cov saw txuas nrog ib txoj kab uas hla 20 mm;Carburizing Qhov tob: 10% ntawm 20 hli = 2 hli;Ua Haujlwm Hardness Qhov tob: 5-6% ntawm 20 mm = 1–1.2 mm ntawm 550 HV;Qhov no tsim ib qho nyuaj, hnav-tiv taus nto thaum khaws cia cov ductile core kom nqus cov khoom hnyav.

3. Kev kho cua sov:quenching: Tom qab carburizing, cov khoom yog quenched rau xauv rau hauv lub hardness (800 HV rau chains, 600 HV rau shackles);Tempering: Tswj tempering (piv txwv li, ntawm 200-250 ° C) kho cov tub ntxhais lub zog, ua kom muaj zog thiab qhov yuav tsum tau tawg quab yuam ntawm 280-300 N / mm². Over-tempering txo hardness, thaum under-tempering txaus ntshai brittleness.

4. Txoj Cai Sib Nqus: Hardness: Lub siab tawv tawv tiv taus hnav los ntawm cov khoom siv abrasive;Lub zog: Core toughness tiv thaiv nkig tawg nyob rau hauv tensile loads.SCIC tswj cov carburizing qhov tob thiab tempering tsis kom tsis txhob dhau brittleness thaum ntsib cov neeg siv khoom tshwj xeeb.

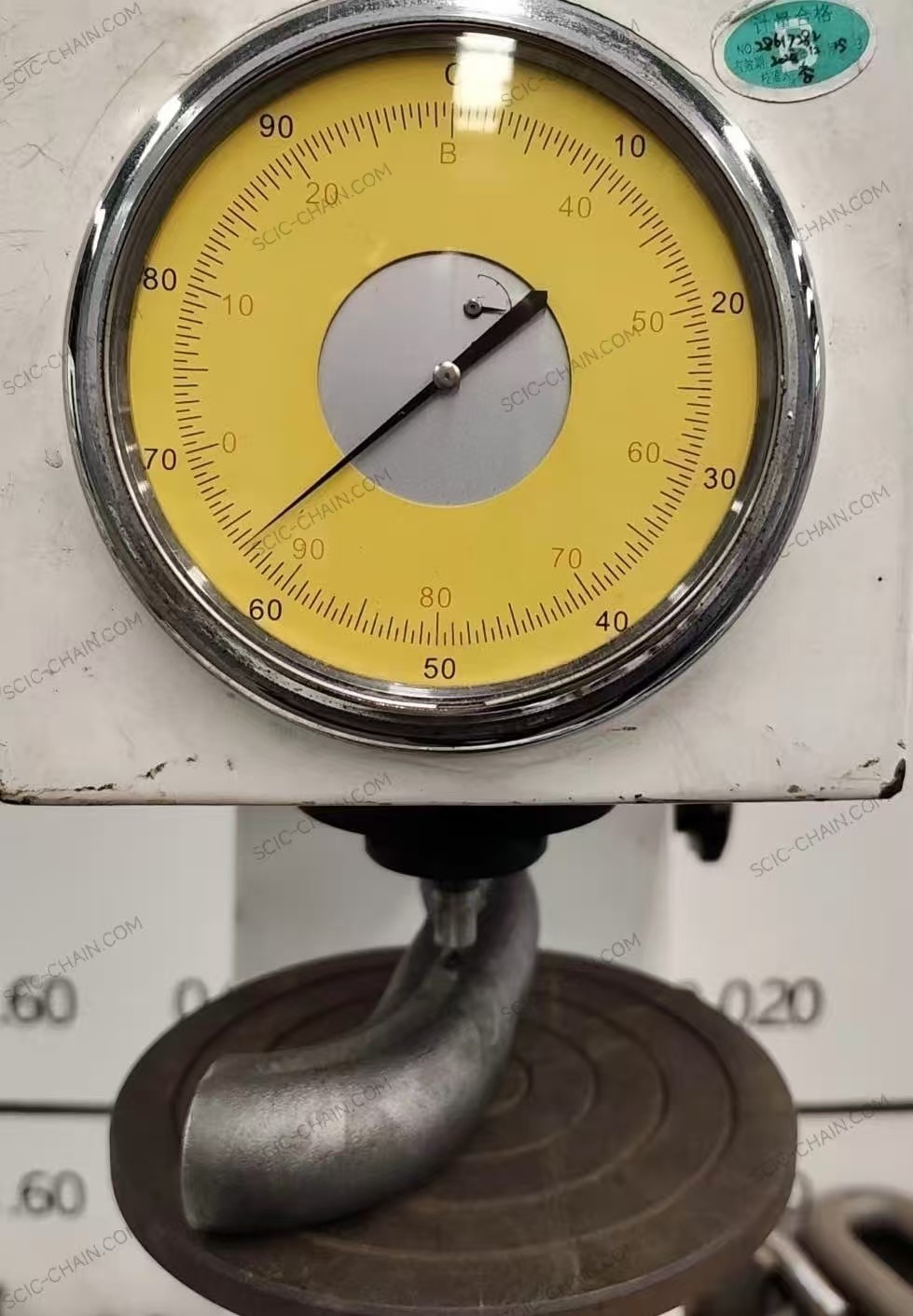

(chain txuas nrog siab carburized nto hardness)

(chain txuas nrog siab carburized nto hardness, tom qab tawg quab yuam xeem)

Peb cov txheej txheem tsim khoom yog kev tswj xyuas nruj kom ua tiav qhov sib npaug zoo tshaj plaws ntawm hardness thiab lub zog. Los ntawm qhov tseeb carburizing thiab kev kho cua sov, peb xyuas kom meej tias pebchains thiab shacklesmuaj ib qho nyuaj, hnav-resistant nto thaum tuav lub hauv paus tawv los tswj cov dynamic loads hauv koj cov haujlwm. Qhov kev sib npaug no yog qhov tseem ceeb rau kev ua kom lub neej ntev thiab kev ntseeg siab ntawm cov cuab yeej siv.

III. Ua kom lub neej ntev los ntawm kev ua haujlwm thiab kev saib xyuas

Txawm nrogzoo chains thiab shackles, kev ua haujlwm kom raug thiab kev saib xyuas yog qhov tseem ceeb rau kev ua kom lub neej ntev tshaj plaws hauv cov cement Hoobkas thoob elevator. SCIC muab cov lus qhia hauv qab no rau cov neeg siv khoom:

Cov Lus Qhia Txog Kev Kho Mob

1. Kev tshuaj xyuas tsis tu ncua:Tshawb xyuaschains thiab shacklesrau hnav cov cim, xws li elongation (piv txwv li,> 2-3% ntawm qhov qub ntev), deformation, los yog nto tawg. Kev tshawb pom ntxov tiv thaiv kev ua tsis tiav.

2. Lubrication:Siv cov roj nplua nyeem kub, hnyav hnyav los txo kev sib txhuam thiab hnav. Lubricate txhua 100-200 teev ua haujlwm, nyob ntawm cov xwm txheej.

3. Kev soj ntsuam nruj:Ua kom pom cov saw nro kom tsis txhob poob qis (ua rau jerking) lossis overtightening (nce hnav). Kho raws SCIC cov kev qhia tshwj xeeb.

4. Kev hloov raws sij hawm:Hloov cov khoom hnav lossis puas tsuaj tam sim ntawd los tiv thaiv cascading tsis ua haujlwm. Piv txwv li, ib tug deformed shackle yuav tsum tau swapped tam sim ntawd.

5. Kev ua haujlwm zoo tshaj plaws:Ua haujlwm nyob rau hauv cov kev txwv tsim (xws li, tsis txhob overloading tshaj 280-300 N / mm² rhuav tshem lub peev xwm) kom txo tau qhov kev ntxhov siab.

Txhawm rau ua kom lub neej ntev tshaj plaws ntawm koj cov chains thiab shackles, ua raws li cov kev coj ua no: tsis tu ncua tshuaj xyuas kev hnav, xyuas kom muaj lubrication zoo, saib xyuas cov saw nro, thiab hloov cov khoom puas sai. Los ntawm kev ua raws li cov lus qhia no thiab kev ua haujlwm nyob rau hauv kev txwv tsim, koj tuaj yeem txuas ntxiv kev ntseeg tau thiab kev ua haujlwm ntawm koj lub thoob elevator.

Case Study: Kev cuam tshuam tiag tiag hauv ntiaj teb

Scenario:

Lub tuam txhab cement tau ntsib ntau qhov kev sib txuas ntawm cov saw hlau tsis ua haujlwm, nrog lub sijhawm poob qis ntawm 10 teev hauv ib lub hlis vim cov saw hlau tsuas yog 600 HV hardness thiab ntiav carburizing qhov tob. Qhov no ua rau cov nqi kho siab thiab poob ntau lawm.

Kev daws:

Lub Hoobkas tau txais SCIC's case-hardened round link chains:

- Parameters: 30 hli txoj kab uas hla, 800 HV nto hardness, 3 hli carburizing qhov tob, 1.8 hli zoo hardness ntawm 550 HV, 290 N / mm² tawg quab yuam.

- Kev Kho: Kev tshuaj xyuas ob lub lis piam, lubrication txhua 150 teev, thiab kev hloov kho nro.

(chain txuas nrog txhim kho carburizing qhov tob rau 10% txuas kab)

IV. Cov txiaj ntsig

1. Lub sij hawm poob: Txo 80% (mus rau 2 teev / hli).

2. Lifespan: Chains kav 18 lub hlis (vs. 6 lub hlis dhau los).

3. Kev Txuag Nqi: Cov nqi kho mob poob 50% txhua xyoo.

Qhov no qhia tau hais tias SCIC cov khoom ua tau zoo thiab cov kev taw qhia txog kev saib xyuas tau txais txiaj ntsig zoo li cas.

V. Xaus

1. Xaiv qhov zoo Cheebtsam:SCIC's DIN-raws li chains thiab shackles, backed los ntawm superior tsim thiab zoo tswj, xyuas kom meej kev nyab xeeb thiab efficiency nyob rau hauv cement Hoobkas thoob elevator.

2. Sib npaug Hardness thiab Strength: Peb cov txheej txheem raug tsim raws li cov neeg siv khoom tshwj xeeb, xa cov hnav tsis kam thiab lub peev xwm thauj khoom.

3. Maximizing Lifespan: Cov kev taw qhia txog kev saib xyuas ua kom muaj kev ntseeg tau ntev.

Los ntawm kev koom tes nrog SCIC, cov neeg siv khoom tau nkag mus rau cov kws tshaj lij cov hlua thiab cov shackles, haum rau lawv cov kev xav tau, thiab txhawb nqa los ntawm cov tswv yim pov thawj los txhim kho kev ua tau zoo thiab txo cov nqi.

Lub sij hawm xa tuaj: Plaub Hlis-21-2025